Case

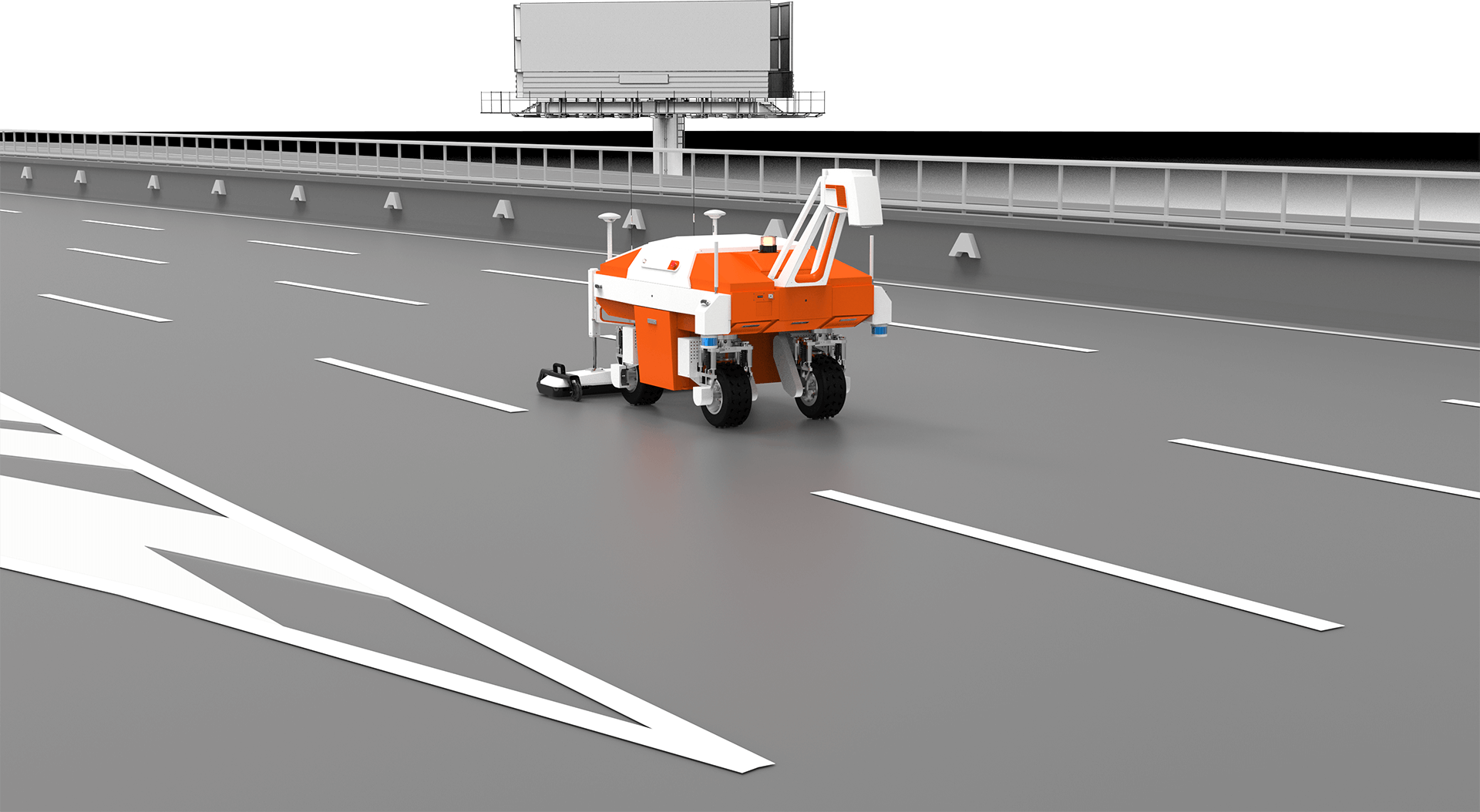

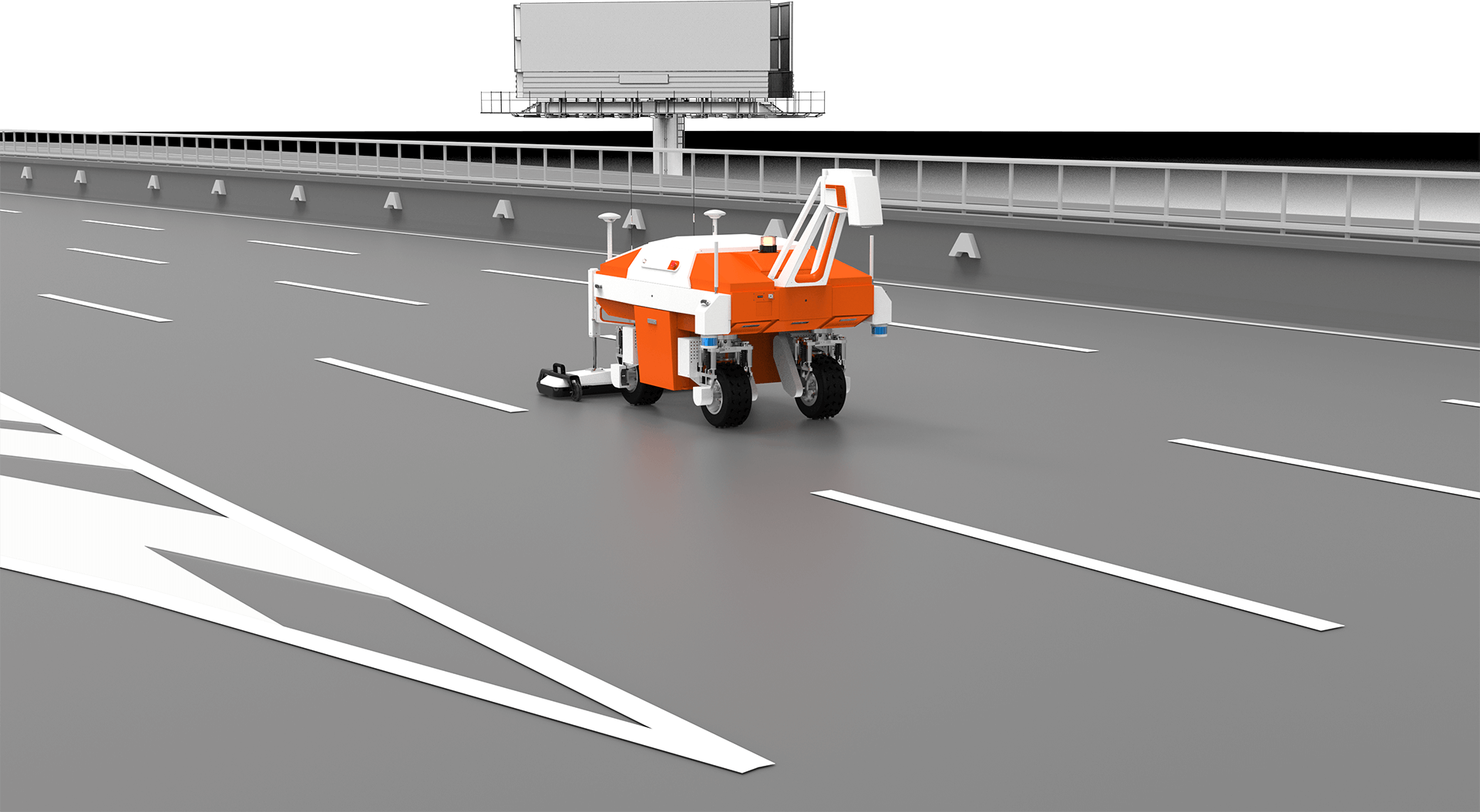

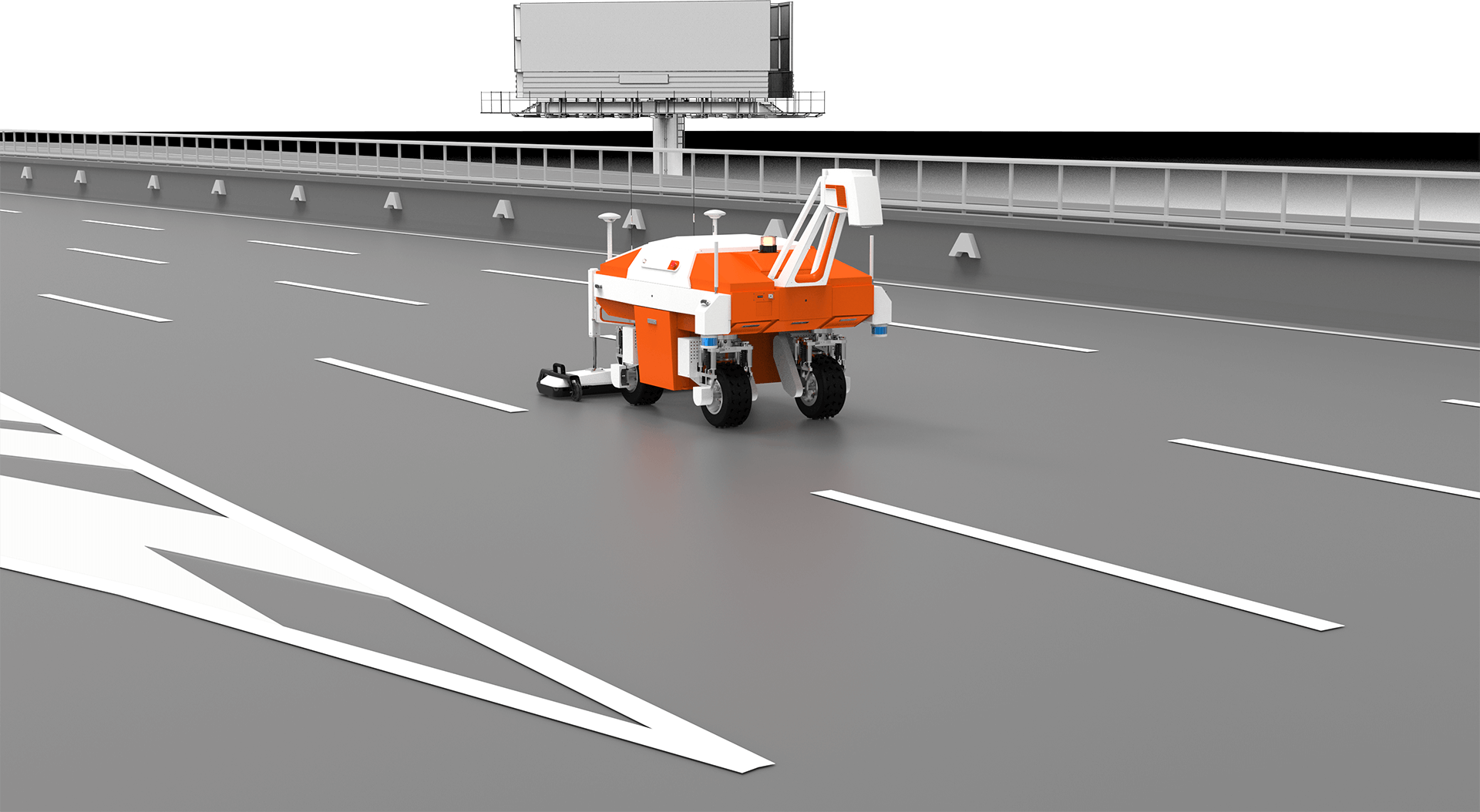

The World’s First Road Pavement Health Robot Inspection System Solution

Case

Case

The World’s First Road Pavement Health Robot Inspection System Solution

Case